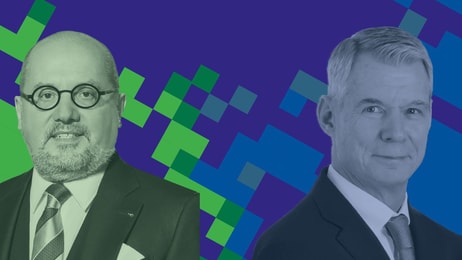

Tackling over-capacity: An interview with the Steel Manufacturers Association (SMA)

Compromised capacity utilisation, the influx of cheap imports, and a serious erosion of profitability have forced the closure of several high-profile steel plants in the last three years.

With excess steel flooding the market, steel prices have plunged and a number of regional governments have attempted to stem this tide of negativity with import taxes or energy subsidies.

The problems facing the global steel business are well documented.

The World Steel Association (worldsteel) claimed in October that global steel demand was through the bottom of this cycle amid the escalated uncertainties, though it acknowledged that the steel industry environment remains challenging.

... to continue reading you must be subscribed