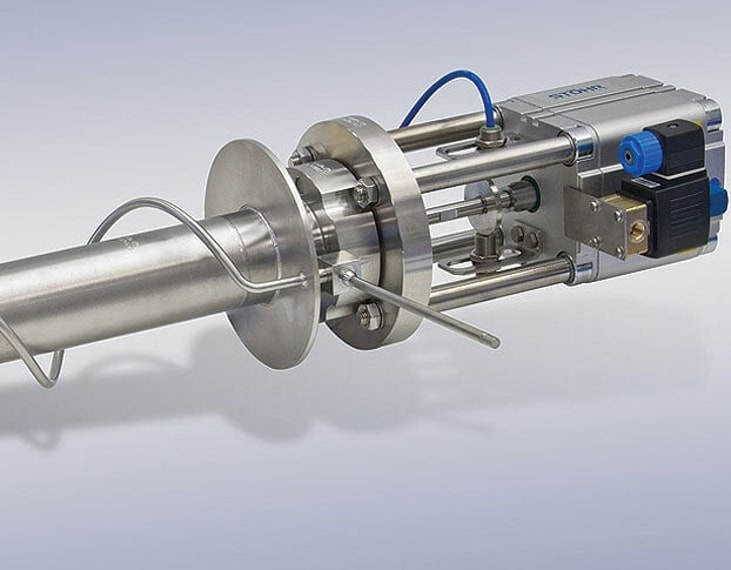

Innovative cryogenic valves introduced by Boiswood

A new range of novel cryogenic valves from STÖHR ARMATUREN (Stoehr) has been introduced by Boiswood, a UK supplier of gas and liquid pressure control equipment.

A major advantage of the patented FREES valves for vacuum jacketed pipes is that they can be installed in any position, making it possible to reduce the length of pipework required.

Positioning the valves horizontally, for example, can allow installation in height restricted locations.

Another advantage is that valves’ clearance volume is reduced by up to 80%, making them cleaner to operate and quicker to purge as there is less dead space to retain media or contaminants.

... to continue reading you must be subscribed