PolarTech product highlights CO2 as an effective cleaning media

PolarTech, based in Esbjerg, Denmark, has developed and patented a cleaning technology which uses liquid CO2 for cleaning and maintenance processes.

PolarTech, based in Esbjerg, Denmark, has developed and patented a cleaning technology which uses liquid CO2 for cleaning and maintenance processes.

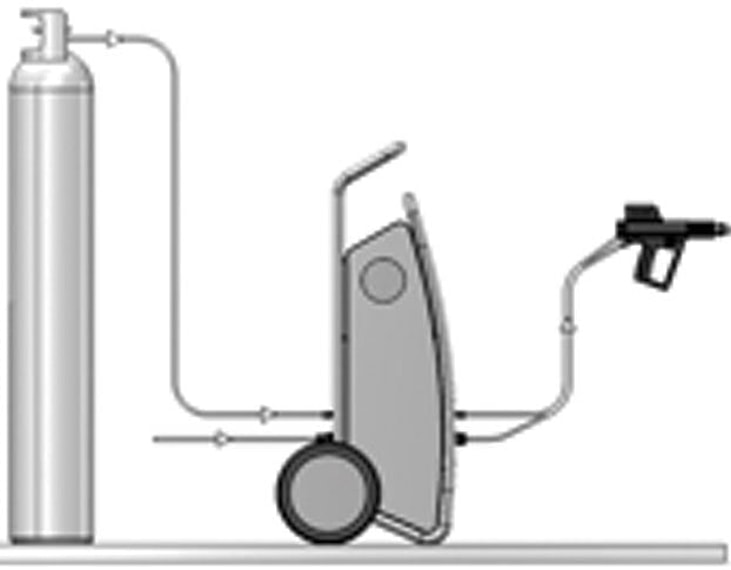

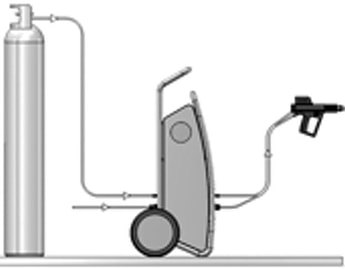

The company has developed a manual system that works like sandblasting, in principle. The equipment is connected to compressed air, electricity and liquid CO2 either from cylinders or larger tanks.

The CO2 is recycled from other industrial processes. PolarTech’s technology can minimise or even replace the use of other existing environmentally damaging cleaning processes.

... to continue reading you must be subscribed