Teesing develops sustainable hydrogen filling option

With the future fuel for the automotive industry looking likely to be hydrogen – one company has aimed to resolve a problem before the gas makes it to pump and public use.

Netherlands headquartered Teesing has spent years looking for a solution to the problem of expansion when hydrogen is being dispensed at the pump to the customer.

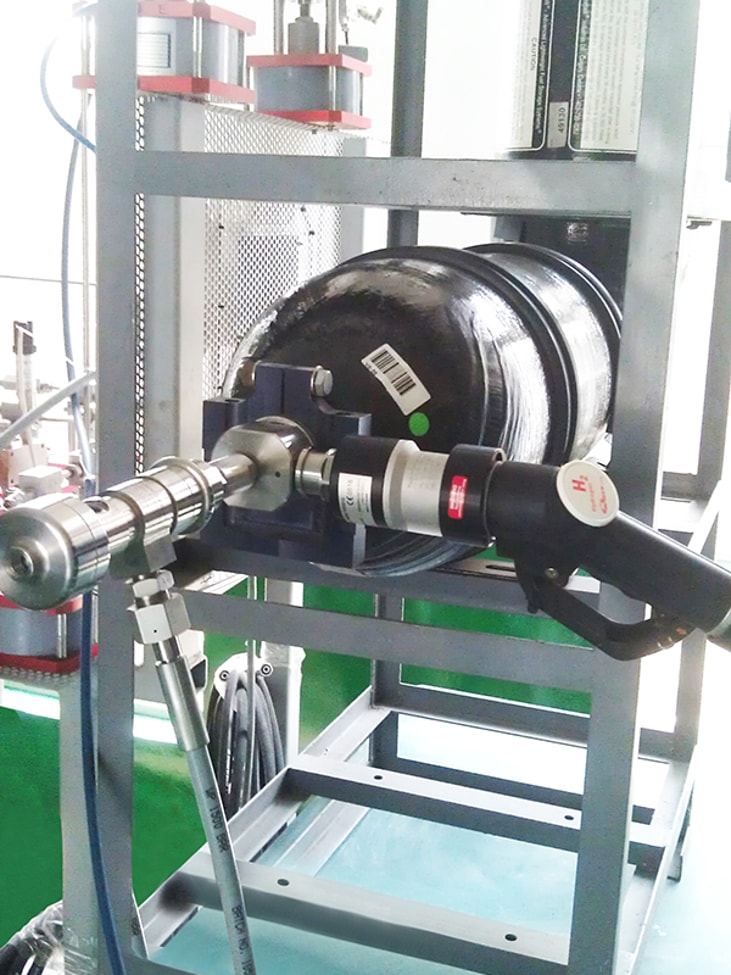

In the future, real integration and acceptance of hydrogen vehicles in our society will depend partly on the critical issue of ease of use for the public and familiarity with this ‘new’ type of energy. As human beings we are more quickly inclined to switch if things become cheaper, faster, more efficient, safer or more sustainable. Teesing recently finished the PusH project, in which it successfully filled cylinders fast and efficiently with hydrogen at 700 bar.

Why 700 bar?

... to continue reading you must be subscribed