Teesing gets patents for hydrogen refuelling technology

Teesing B.V, a Netherlands-based connectivity solutions provider, has been assigned several patents for its unique, filling technique for hydrogen (H2) refuelling.

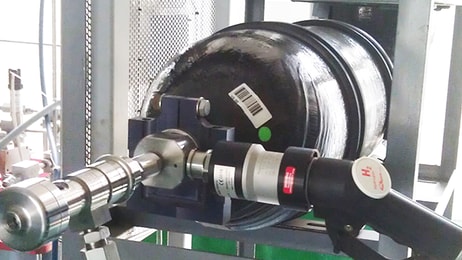

In order to supply H2 at 700 bar, the company’s Pressurising Using Hydraulics (PUsH) system eliminates the need for pre-cooling by implementing a compressor, with the system filling fuel cell vehicles (FCVs) with both H2 and water.

The technology, which Teesing has been developing since 2009, has now been completed through to level TRL4 and is set to be validated in a relevant, undisclosed industrial application, according to the business.

... to continue reading you must be subscribed