The Huntingdon Fusion Techniques PurgExtra

The Huntingdon Fusion Techniques’s (HFT) PurgExtra® enables operators to purge tube and pipe joints from 1-24” diameter.

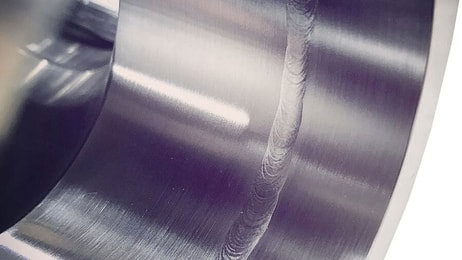

PurgExtra allows extra argon (Ar) gas into the welding zone, helping to cool the weld zone dramatically. The extra gas also helps to remove the gases that are expelled by the outgassing, which occurs as the metal is being heated. The extra gas flow will prevent these expelled gases from combining with the hot metal and oxidising, which would otherwise cause the metal to discolour and lose its corrosion resistance and possibly introduce defects that would cause loss of joint integrity.

PurgExtra comprises of two inflatable dams connected by a heat resistant, highly flexible gas hose that has the unique IntaCal® gas release system. IntaCal allows the dams to be inflated correctly and then releases the inert gas to safely purge the space between the dams. The low profile IntaCal Valve replaces the old fashioned, bulky complicated valves and eliminates the need to make adjustments to flow rates.

... to continue reading you must be subscribed