The new Leybold VARODRY

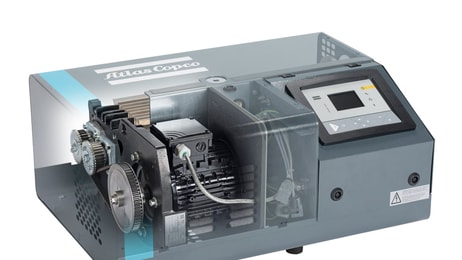

Leybold, pioneer of vacuum technology, has launched the new VARODRY, a 100% oil-free, dry compressing screw vacuum pump.

Screw pumps are currently state-of-the-art in the field of industrial vacuum pumps. The VARODRY will initially be available in the sizes VD65 (65m³/h) and VD100 (100m³/h). The sizes VD160 and VD200 are already in preparation.

What qualifies the pumps of the VARODRY series is their excellent suitability for the manufacturing industry. The reason: In industrial processes, pumps do not only need to handle clean air, but also dirt, particles, outgassing of media and vapours.

... to continue reading you must be subscribed

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)