Union Process launches pilot-sized mill for cryogenic grinding

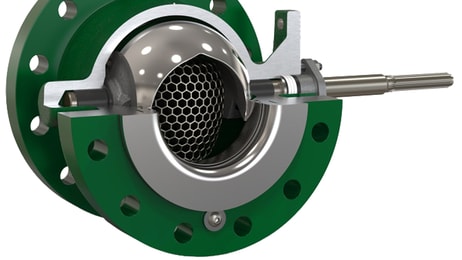

Union Process, Inc., manufacturer of particle size reduction and dispersing equipment, has launched a newly designed pilot-sized mill for cryogenic grinding with a specially designed stainless steel insulated cryogenic milling chamber.

Chuck Major, Sales Manager for Union Process, noted, “This unique mill features a special cryogenic controller with temperature probe to help maintain a consistent liquid nitrogen level in the milling chamber.”

The S5 pilot-sized mill has a cryogenic cover with vent and phase separator, along with two charging ports for added versatility. The mill has an actuated ball valve assembly that enables remote discharge of the liquid nitrogen slurry.

... to continue reading you must be subscribed

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)