Velo3D showcases additive manufacturing tech at new European centre

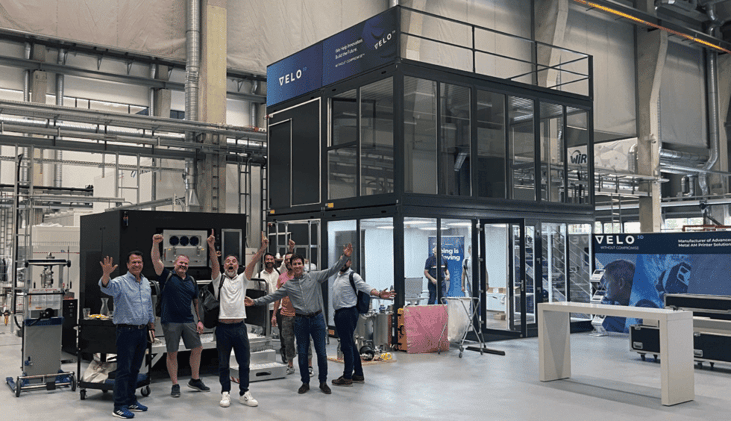

Additive manufacturing (AM) specialist Velo3D has opened its European Technology Center in Augsburg, Germany, which will act as the hub for the company’s operations in the region.

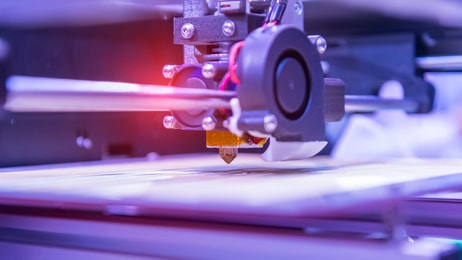

The centre, which spans more than 110m2, contains a lab area featuring a Velo3D Sapphire printer, and will be used to showcase its end-to-end AM solutions in addition to acting as a location for hosting training sessions and conducting meetings with customers and partners.

Having shipped its first Sapphire printer three years ago, the company has experienced ‘tremendous growth’ across all its key industries, according to Benny Buller, Founder/CEO, Velo3D.

... to continue reading you must be subscribed