White paper: Maximise safety and efficiencies with wire bushing

To design safe electrical systems for hazardous locations, you’ll have to pay close attention to every electrical component that you use—including any wire bushings.

In the past, it was difficult to find feed-throughs and wire or line bushings that you could customize to your needs while meeting compliance standards for hazardous locations. Now, however, there’s an approach to feedthrough and wire bushing design that makes it far easier to meet all the relevant regulations without sacrificing design freedom. The key to this approach involves the use of epoxies to create hermetic seals around the wires.

This white paper from electrical safety solutions specialist Douglas Electrical Components (DEC) focuses on the crucial role of wire bushings in designing safe electrical systems for hazardous locations.

Highlighting two lesser-known design features of Douglas Electrical Components’ UL Explosion-proof and ATEX/IECEx rated line bushings:

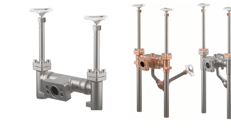

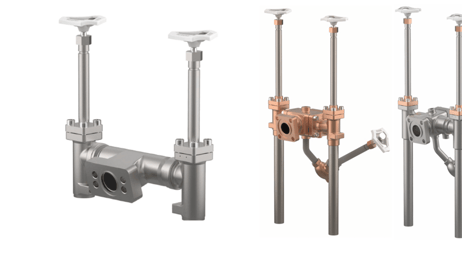

- Full chemical compatibility: Epoxy offers high-end fatigue properties and resistance to environmental stress cracking, ensuring long-lasting sealing in the field.

- Combined explosion and process seal: The line bushings provide a true hermetic process seal, simplifying installations in hazardous locations.

DEC’s whitepaper not only addresses the challenges of hazardous location standards but also introduces innovative solutions to meet evolving industry needs.