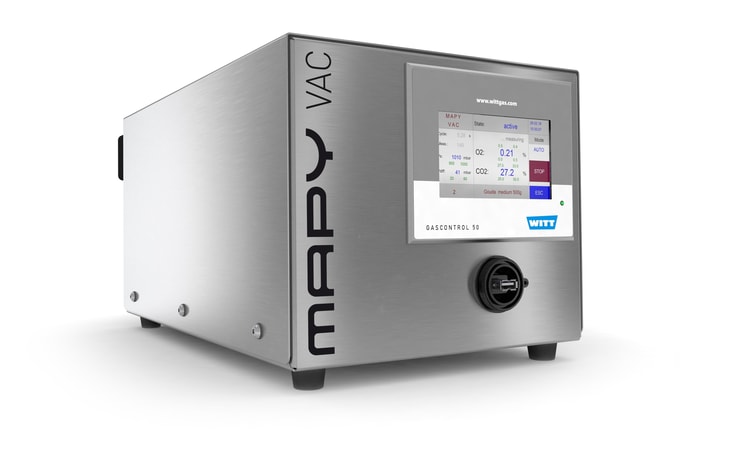

Witt introduces MAPY VAC for tray-sealers and thermoformers in food packaging

Gas-related equipment manufacturer Witt-Gasetechnik has released a new inline gas analyser which checks the modified atmosphere of packages processed in tray-sealers and thermoformers before the packages are finally sealed.

The new MAPY VAC inline gas analyser checks the vacuum generated in the packaging machine first, then measures the incoming inert gas in the sealing tool itself. Thus, the measurement is performed in sync with the machine cycle.

The device accurately and reliably measures oxygen (O2), as well as carbon dioxide (CO2) (if required), in the 0 to 100 percent range. The measured values are displayed in increments of 0.01% for gas concentrations below 10% and in increments of 0.1% for gas concentrations above 10%.

... to continue reading you must be subscribed