Witt launches new leak testing technology for MAP packaging

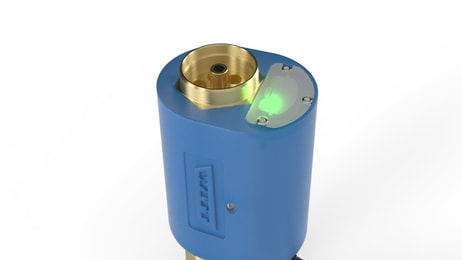

Gas technology manufacturer Witt has unveiled its new LEAK-MASTER® PRO 2 to detect even the smallest leaks in protective gas packaging.

Leak testing with the LEAK-MASTER® PRO 2 is carried out with CO2 as the tracer gas, already contained in most inert gas packaging.

The PRO 2 is equipped with a number of innovations that increase the performance for the user. For example, with optimised chamber size and compressed air instead of a vacuum pump to generate the vacuum.

... to continue reading you must be subscribed