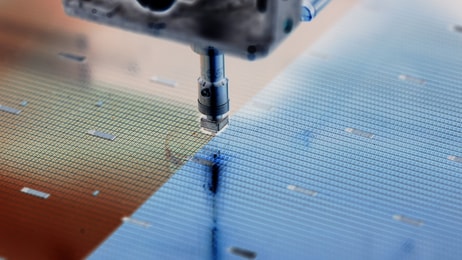

Xenon recovery system for semiconductor industry

Air Products declared this week that it has introduced its new XeCoverysm on-site xenon recovery service for the semiconductor and MEMS industries, offering cost-effective benefits for manufacturers facing ever-rising prices.

As has been the case for a selection of gases in recent months, the cost of xenon has been on the rise due to a number of novel new uses for the rare gas. With demand and prices on the rise, there is a growing concern that cost or availability will hamper its applicability.

This is the situation within semiconductor manufacturing, where the price of xenon has risen while device prices have continued to decline. Air Products’ new system however, could alter the dynamics in the industry though as semiconductor manufacturers can now recover and reuse the crucial gas, saving valuable time and money in the process.

“Because of high xenon recovery rates, customers currently using xenon in their manufacturing processes could improve their security of supply and see savings of more than 50% in their cost of xenon by utilising XeCovery recovery service, without incurring any additional capital outlay for equipment,” said Gene Karwacki, Commercial Development Manager for Air Products.

... to continue reading you must be subscribed