Air Products officially opens world-class SMR in Texas

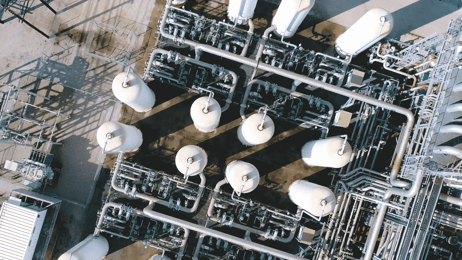

Air Products yesterday held a ribbon-cutting event in Texas where the Tier One corporation has invested more than $350m to build, own and operate a world-scale steam methane reformer (SMR).

The SMR, located at the Covestro LLC Baytown industrial park, is producing hydrogen (H2) and carbon monoxide (CO) to be supplied at Baytown to Covestro and to other customers linked to Air Products’ Gulf Coast H2 and CO pipeline networks.

“Our decades-long relationship with Covestro and its predecessor companies continues to grow with this new facility in Baytown,” said Marie Ffolkes, Air Products’ President of Industrial Gases Americas.

... to continue reading you must be subscribed