Burckhardt Compression passes 1m operating hours with Laby-GI compressors

An essential part of any liquefied natural gas (LNG) carrier, Burckhardt Compression Laby-GI fuel gas compressor systems has passed one million operating hours for MAN ME-GI engines.

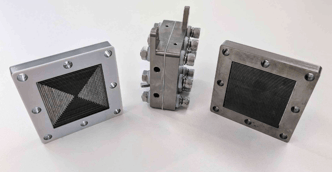

The compressors are designed to help manage operating pressures of engines and re-liquefaction plants onboard LNG carriers.

This management is necessary as, due to boil-off gas being produced as the LNG warms up during storage and transportation, it must be used either as fuel or become re-liquefied.

The Laby-GI compressors achieve this by being specifically designed to handle gases at low temperature and high pressure while also meeting the requirements for operation at sea.

... to continue reading you must be subscribed