Chart lands contract for Babcock’s ecoSMRT® LNG boil-off gas recovery system

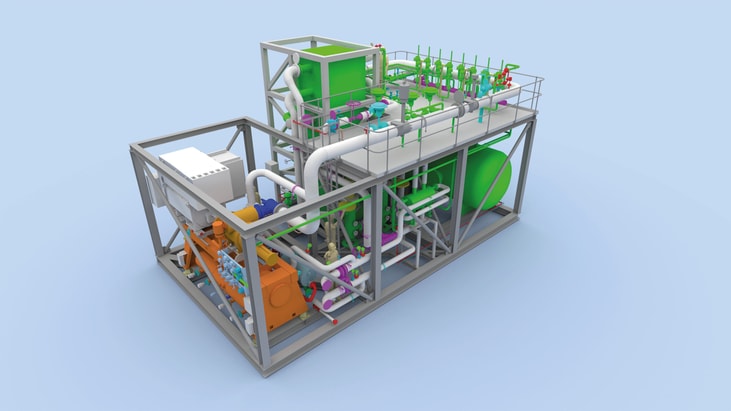

Chart Energy & Chemicals, a subsidiary of Chart Industries, will provide 12 brazed aluminium plate fin heat exchangers (BAHX) for Babcock’s ecoSMRT® liquified natural gas (LNG) boil-off gas recovery system.

Boil-off gas recovery is fundamental to increasing cost efficiencies and environmental credentials of LNG ship fleets.

Babcock’s patent-pending ecoSMRT® can be installed on new vessels and retro-fitted on to older ships. It can be deployed on large and small carriers as well as bunkering vessels.

... to continue reading you must be subscribed