Cold chain solutions for life science segment

TOMCO2 Systems is launching phasetwo Cold Chain Solutions this year to provide the equipment necessary for laboratories, pharmaceuticals, universities, and research centers globally.

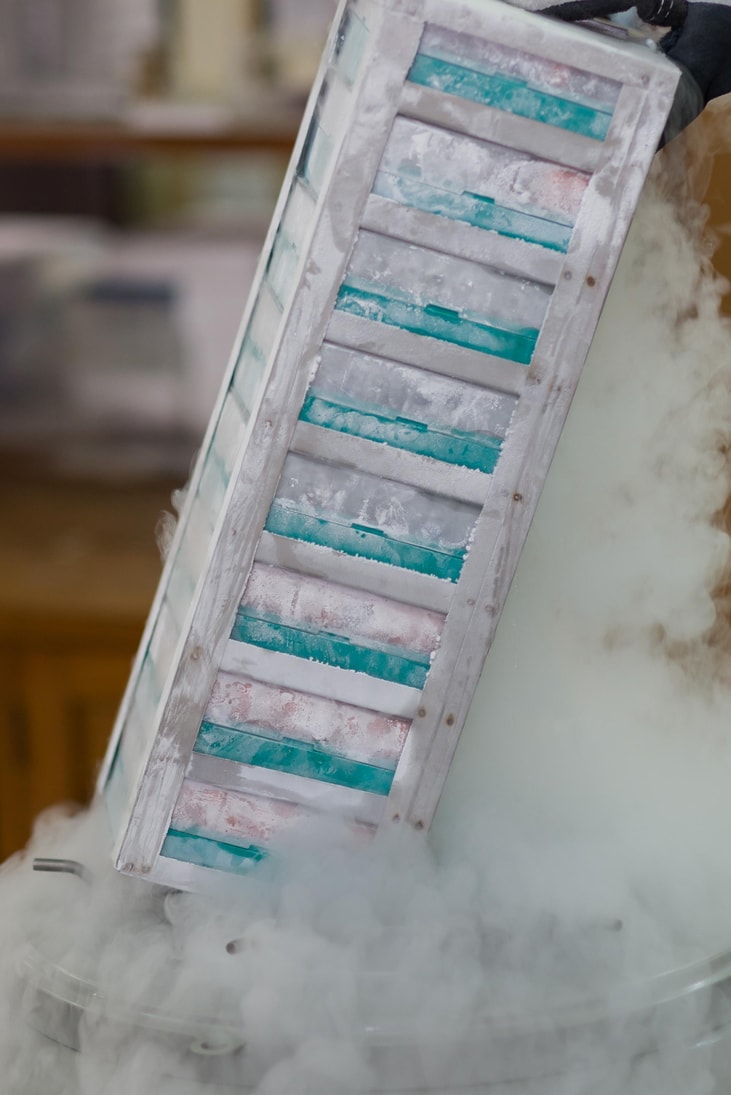

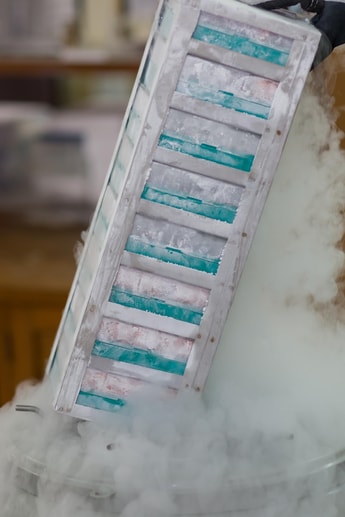

Its solutions will include the critical infrastructure in packaging, storage, shipping, and monitoring of samples that require cold storage such as dry shippers, control rate freezers, cryogenic preservation, and on-demand dry ice production. phasetwo’s cryogenic freezers are specifically designed to meet the demanding freezing processes of living cells while preserving their viability. Loganville, Georgia-based TOMCO2, a leading provider of bulk CO2 storage and distribution solutions, revealed its plans for phasetwo with gasworld US ahead of launch later this year.

How did phasetwo come to fruition? Why did TOMCO2 see the need to do this new venture?

... to continue reading you must be subscribed