A Special Report from Huntingdon Fusion Techniques

Many of the metallic materials in common use now are prone to contamination when in contact with atmospheric gases, such as oxygen, nitrogen, and hydrogen.

This is particularly the case when this contact occurs at the high temperatures prevailing in fusion welding.

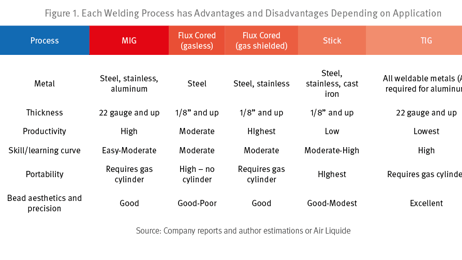

Control of contamination can be affected in the majority of cases by shielding the local welding area with a protective inert gas such as argon, as in GTAW (TIG welding) or by introducing a protective slag as in MMAW (stick electrode welding). With many metallic materials however, including some titanium and nickel alloys, more stringent precautions are necessary and to ensure satisfactory weld quality the entire joining process needs to be undertaken inside a vessel from which all potential contaminating products have been removed.

... to continue reading you must be subscribed