Gas Lab puts biogas in the spotlight for carbon capture

Industrial gas manufacturer-exporter SS Gas Lab (Gas Lab) is advancing the environmental and profit potential of biogas and the utilisation of ‘waste’ carbon dioxide (CO2) through its CO2 recycling solutions.

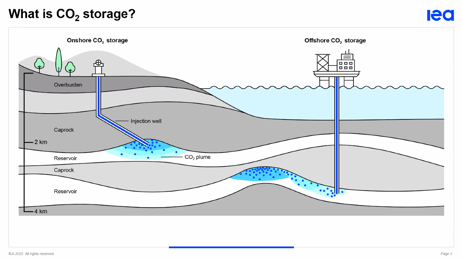

As global energy sectors focus on meeting ‘net zero’ targets, the reduction and elimination of CO2 – a gas that Gas Lab see as being mistakenly treated as waste – has seen entire industries spawn around carbon capture, utilisation, and storage (CCUS).

Sustainable energy alternatives such as biogas – used to decarbonise hard-to-abate sectors such as heavy transport – produce CO2 as a by-product. According to Gas Lab, this CO2 is not considered by many companies as something capable of being captured and either utilised or sold.

... to continue reading you must be subscribed