Gas Sensing Solutions CO2 sensor increases diver safety

Gas Sensing Solutions (GSS) and AP Diving have collaborated to develop the CozIR™ Wide Range CO2 sensor that increases diver safety.

Recreational diving is enjoyed by people around the world and diving with rebreather equipment is booming. Rebreather technology recirculates the air, removes the CO2 and tops up the oxygen level. As a result, a small tank of air and a small tank of oxygen is all that is needed, rather than big tanks of compressed air.

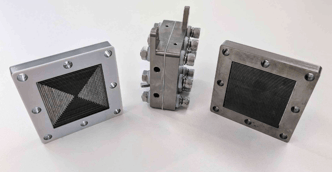

One limitation is the CO2 removal. This is done chemically by passing the exhaled gas through a scrubber containing soda lime but, of course, this has a finite absorption capability. The capability of the scrubber depends on the user refilling with the correct soda lime at the correct time and unfortunately it has been known for users to get it fatally wrong.

... to continue reading you must be subscribed