Haldor Topsoe to build demonstration plant in Denmark

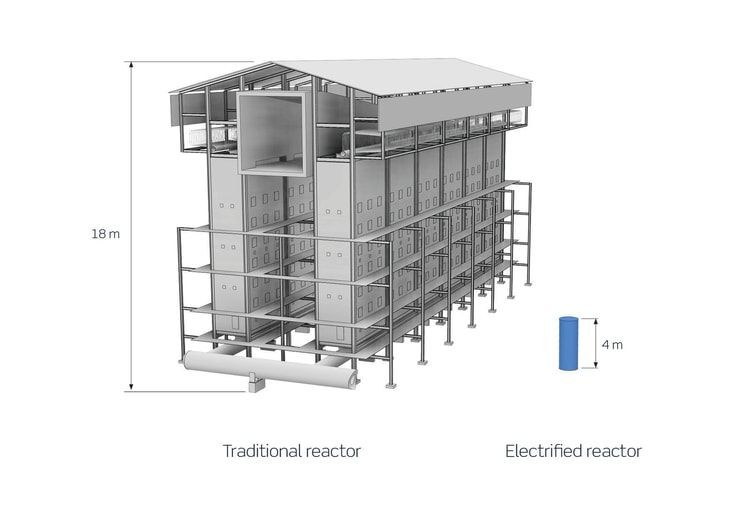

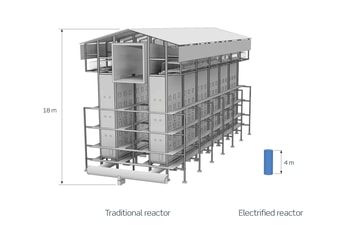

Haldor Topsoe will build a demonstration plant to produce cost-competitive CO2-neutral methanol from biogas and green electricity.

The 10kg/hour plant will demonstrate the Danish catalysis company’s eSMR MethanolTM technology, which exploits the full carbon potential of biogas by utilising the 40% CO2 content.

The technology heats the process using green electricity from wind turbines or solar panels instead of natural gas.

... to continue reading you must be subscribed