Huntingdon Fusion Techniques White Paper for welding of Zirconium and its alloys

Huntingdon Fusion Techniques (HFT), specialist in gas weld purging techniques, has written a new White Paper – Welding of Zirconium and its Alloys.

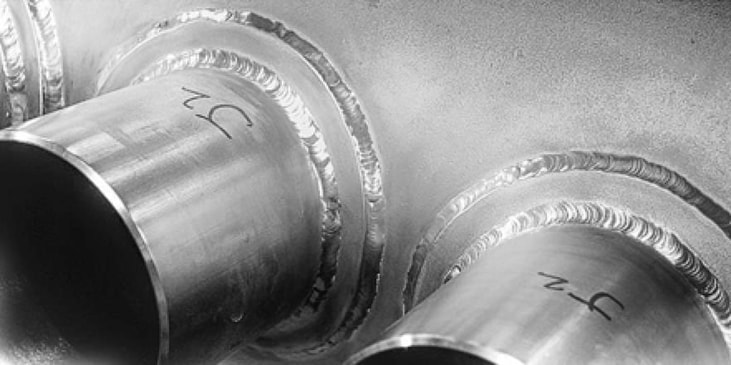

The exclusive paper discusses the physical properties of Zirconium and its principal alloy zircaloy, deeming it to be unmatched by most other metallic materials due to the combination of mechanical strength, corrosion resistance and their high temperature stability. These qualities make them attractive for use in sectors as diverse as biochemical, nuclear, aerospace and petrochemicals. More specifically, zircalloy, is used in the manufacture of pressure vessels, heat exchangers and nuclear power plants.

The White Paper goes on to consider the welding preparations involved with Zirconium to avoid contamination and the two welding processes – Electron Beam (EBW) and Gas Tungsten Arc (GTAW).

... to continue reading you must be subscribed

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)