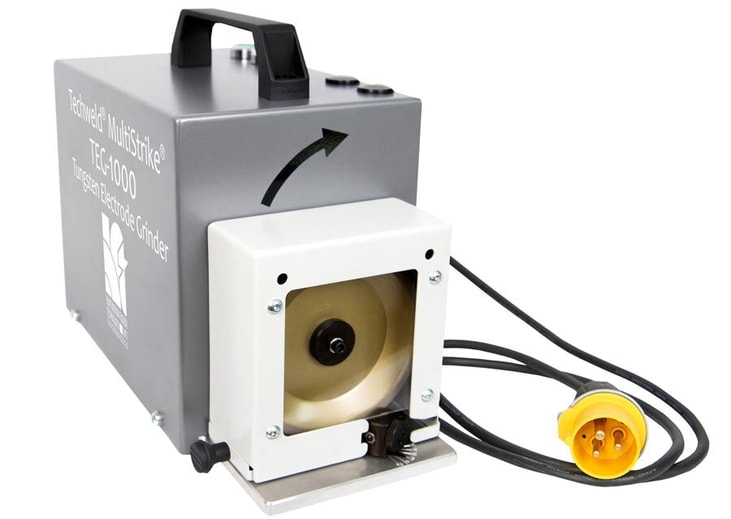

HFT’s Tungsten Electrode Grinder back by popular demand

Huntingdon Fusion Techniques (HFT®) has re-initiated the manufacturing of the TEG-2 Tungsten Electrode Grinder, which retired from their product range a number of years ago, under the new name of TEG-1000.

The use of the TEG-1000 Grinder will give repeatable Tungsten Electrode points every time, enabling consistent repeatable arc performance and welding results. Sizes 1.0 to 3.2mm can be ground as standard, with other sizes catered for on request.

Georgia Gascoyne, the UK-based enterprise’s CEO, explained the reasons for bringing back the device, “Since we stopped manufacturing the TEG-2 Tungsten Electrode Grinder, we’ve been inundated with requests to bring it back into our product range. We are excited to announce that it’s back, with a new modern look and attractive price.”

... to continue reading you must be subscribed