ION Engineering initiates CO2 capture process campaign at TCM

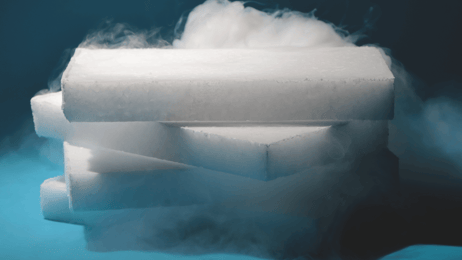

Carbon capture technology company ION Engineering has initiated testing of its proprietary carbon dioxide (CO2) liquid absorbent system at Technology Centre Mongstad (TCM) in Norway.

This latest test campaign at TCM, which is the world’s largest and most advanced carbon capture test facility, aims to further scale-up and validate ION’s CO2 capture technology and reinforce its second generation liquid adsorption system for deployment on an industrial scale.

The Colorado-based company’s technology directs flue gas rich with CO2 into an absorption tower, where its solvent contacts the flue gas and absorbs the CO2. The flue gas, which is then cleansed of CO2, is returned to the stack and safely released into the atmosphere before the CO2-loaded ION solvent is directed to the regeneration section of the process and heated; at which point the CO2 is stripped from the solvent. The captured CO2 is then sent to be compressed and transported for either utilisation or sequestration purposes.

... to continue reading you must be subscribed