MAN Energy Solutions to boost low-carbon cement production with compressor tech

German company MAN Energy Solutions (MAN) is to supply its patented ‘Carbon Capture Heat Recovery’ system to HeidelbergCement Norcem (HeidelbergCement) to help lower emissions in its cement manufacture process.

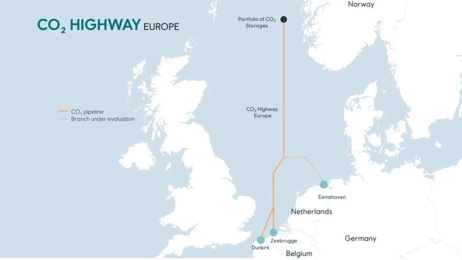

Developed alongside Aker Carbon Capture (Aker), the technology will compress and liquefy carbon dioxide (CO2) at HeidelbergCement’s Brevik, Norway facility before being transported by ship to an underground storage location.

Due to begin in 2024, 400,000 tonnes of CO2 will be captured each year from the facility, around 50% of the factory’s total emissions.

Around a third of the total heat demand from Aker’s plant can be delivered by the CCWHR system allowing for heat recovery from the compressor system.

... to continue reading you must be subscribed