NETL solvent technology for CO2 capture

A patented technology from The National Energy Technology Laboratory (NETL), part of the U.S. Department of Energy (DOE) national laboratory system, offers a cost-effective way to separate carbon dioxide (CO2) and hydrogen sulfide (H2S) from hydrogen (H2), carbon monoxide, (CO), and nitrogen (N2) – enabling low-carbon electricity generation and efficient fuel processing.

This technology is a physical solvent that selectively removes weak acid gases, such as CO2, from high-pressure gas streams composed of CO2 and H2, such as those found in carbon capture, H2 purification, and natural gas sweetening applications. What makes NETL’s solvents unique is its ability to use waste heat rather than electricity to drive the solvent’s regeneration. This translates to cost savings realised by increased efficiency.

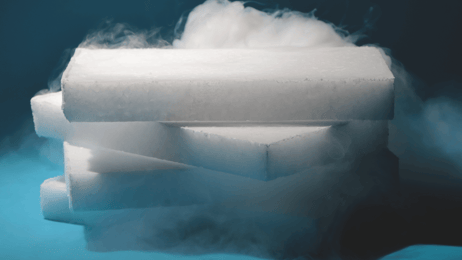

Commercial technologies currently on the market must operate at cooler temperatures (+10 to -10 degrees Celsius), requiring additional energy for the solvents to be chilled and regenerated for further use. NETL’s solvent can operate at higher temperatures (above room temperature) and use waste heat to regenerate. This means chemical plants, power plants, refineries, among others using the solvent can reduce their cost of capturing CO2 from these sources. Using waste heat can increase the amount of net electricity production by up to 50 MW at a 500 MW-scale power plant with CO2 capture.

... to continue reading you must be subscribed