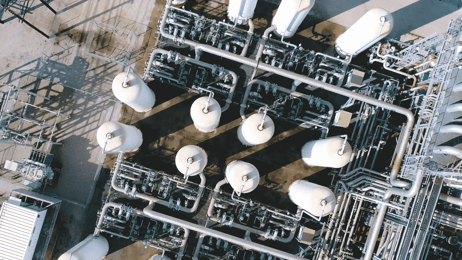

Air Products and Vattenfall in transatlantic CCS effort

Air Products’ CO2 capture, purification and compression system performs a key role in the world's premier demonstration of oxyfuel carbon capture.

On 5th May, Vattenfall, one of Europe’s leading energy companies, held an inaugural ceremony at its research and development facility in Schwarze Pumpe, Germany. The demonstration project is schedu

led to last three years and harnesses Air Products’ purification and compression of oxyfuel combustion flue gas.

David Taylor, Vice President of Energy Businesses at Air Products outlined the firm’s involvement, “At Air Products we have been engaged in innovative oxyfuel solutions for decades. Through working with leading partners all over the world, one of our goals is to develop technologies that reduce the cost of capturing CO2. In working with companies like Vattenfall, which is leading the field in CO2 capture solutions, we can help validate our unique CO2 purification and compression capabilities.”

Taylor went on to add, “These technologies have the potential to fulfill environmental targets around the world.” But it wasn’t just Air Products who extolled the virtues of this partnership, Hubertus Altmann, Head of the Power Plant Unit of Vattenfall in Germany was also pleased with the transatlantic collaboration. He commented, “Increasing efficiency is one of the crucial tasks when developing carbon capture and storage (CCS). In a few years, the technology will be competitive in the market and in order to reach that goal there remains a lot of R&D to be done. It’s important for international companies such as Air Products and Vattenfall to join forces and cooperate on projects like the one we are celebrating today.”

... to continue reading you must be subscribed