Preview: Food for thought

Cryogenic equipment manufacturer Dohmeyer is seeing a consumer shift towards plant-based protein products, driven by Flexitarianism – an increasingly popular diet centred on plant foods with the occasional inclusion of meat that claims to reduce your carbon footprint and improve your health. “Flexitarians are mainly Gen Z, Millennials, Gen X and older Baby Boomers that are concerned about sustainability, health and animal welfare,” Director Fabian Van Damme told gasworld.

“Currently, there are a lot of new plant-based protein products on the market in the meat, poultry, and pork categories. We are also starting to see some more plant-based protein ice cream, cheese, and yogurt style products. The whole plant-based protein products category is a great fit for cryogenics and our cryogenic food processing equipment portfolio.”

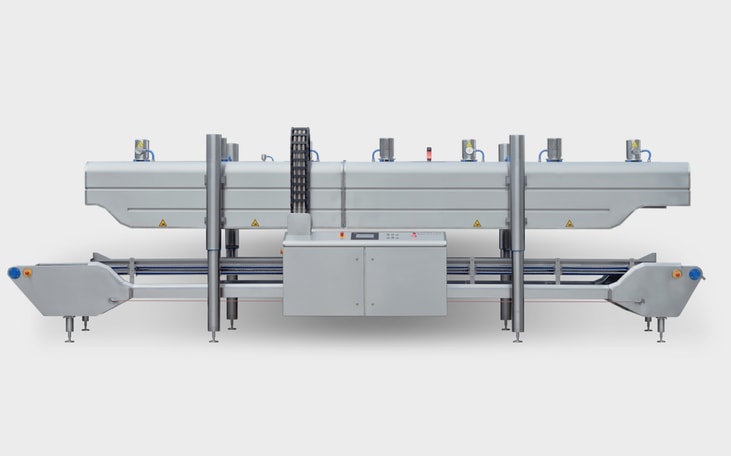

Dohmeyer designs and manufactures a wide range of equipment for all freezing, cooling and temperature control processes. Liquid nitrogen and liquid carbon dioxide (CO2) deliver the ultimate in cryogenic freezing power, but the method of this delivery is where Dohmeyer excels. At its European design facility, Dohmeyer has been trialling and fine tuning a new development that utilises sub-cooled cryogenic liquids, where the liquid is below its normal boiling point for the pressure. By using a fresh new compact sub-cooler and a redesigned injection manifold, significant improvements have been achieved, this new technology is available amongst the company’s product range.

... to continue reading you must be subscribed