SIAD MI and Nel reduce emissions at a hard-to-abate steel mill

Nel Hydrogen Electrolyser, a Norwegian company, has ordered 3 SIAD MI compressors to be used in conjunction with a new 20 MW electrolysis plant that will supply hydrogen to the Ovako rolling mill in Hofors, Sweden.

In a world-first, the Ovako mill will use hydrogen to heat the steel prior to hot forming. The furnaces are currently heated by propane. The new electrolysers will run on green electricity, and so will replace the propane with green hydrogen, meaning that CO2 emissions for the Ovako mill’s total steel operations will be reduced by a whopping 50%.

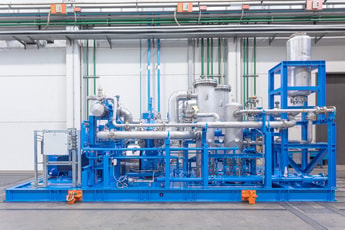

Compression equipment to support the electrolysers will be supplied by two reciprocating compressors (SIAD MI’s model HMS4-4) for green hydrogen, and one for green oxygen ((SIAD MI model MS3-3). SIAD supplied the compressors to Nel under a framework agreement. SIAD MI boasts a specific knowledge at a highly technological level on how to compress hydrogen and, in particular, green hydrogen.

... to continue reading you must be subscribed