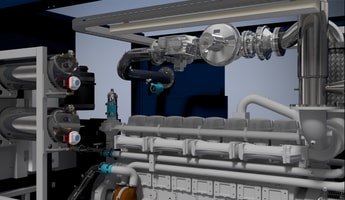

Bell Flow Systems’ TGF600 thermal mass flow metres for syngas

Bell Flow Systems’ TGF600 flow metres are being fitted to environmentally sound syngas engines manufactured in the UK.

Syngas or ‘synthesis gas’ is a combination of hydrogen (H2), carbon monoxide (CO), small quantities of carbon dioxide (CO2) and other trace gases. Syngas is the result of gasification of various carbon-containing fuels to produce a gaseous product with heating value.

The new range of air/gas flow metres combine state-of-the-art electronics technology with application-proven precision flow sensors. Designed for extremely demanding plant operating environments

... to continue reading you must be subscribed