Turbo Containers approved in the US

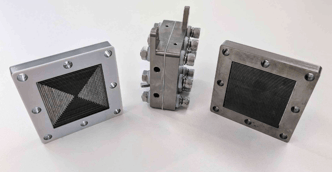

Air Flow North America has received approval to operate its new Turbo Containers in the US for the first time.

One of the biggest issues facing the cryogenics gas industry is making sure that the storage and transfer of extremely cold liquids are stored and transferred safely, efficiently, and with as little loss of product as possible.

Air Flow North America, based in Deer Park, Texas, has announced that the company has received approval from the Department of Energy to operate its new breakthrough Turbo Containers in the US for the first time.

The company has owned a patent on the containers since 2016, which look exactly the same as a regular container in that there is no difference in shape or weight. However, according to Kelly Marull, Sales and marketing manager for Air Flow North America, the Turbo Container changes the game for gas transfer operations. During liquid transfer, usually when there is a low level of liquid left inside of a tank, the transfer slows down or even stop completely because of pressure differential.

... to continue reading you must be subscribed