Norgren’s new high-pressure CNG valve launched

As the prices of ‘traditional’ vehicle fuels continue to rise, so vehicle manufacturers and drivers continue to seek more cost-effective and efficient ways to propel road vehicles.

Among the fastest-growing of these is compressed natural gas (CNG), for which running costs are around 35% of those of gasoline.

The rapid growth in CNG vehicles – of which there are now nearly 15 million worldwide – is being accompanied by an increase in the number of CNG filling stations across the globe, which has now topped 20,000.

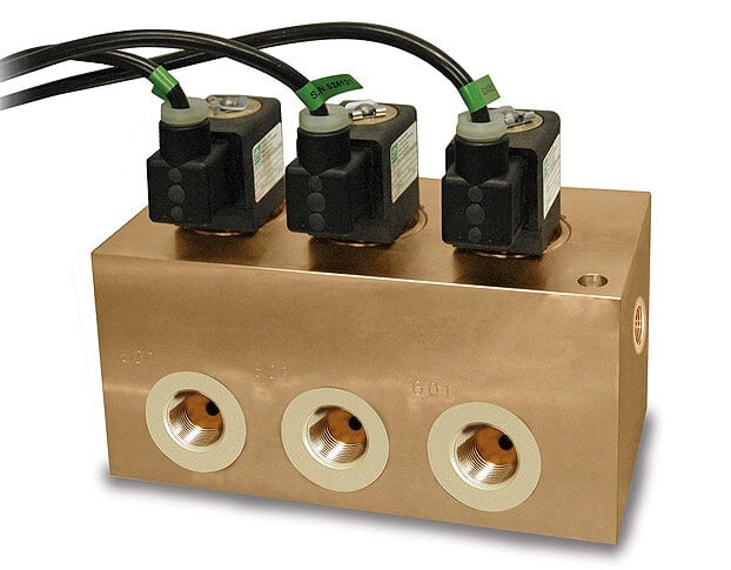

Traditional systems for delivering CNG into vehicles rely on a complex arrangement comprising a regulator, solenoid valve, rotary actuator and ball valve.

... to continue reading you must be subscribed