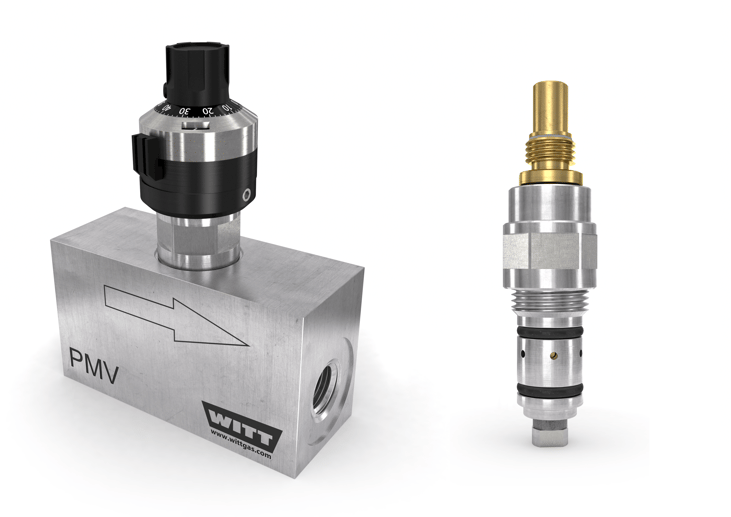

WITT Gasetechnik GmbH presents precision metering valve with sintered body

WITT, manufacturer in the field of gas safety and gas process technologies, presents the precision metering valve (PMV).

Very small gas flow rates down to 30ml/min can be metered by the PMV. The precise flow adjustments can be made in the pressure range up to 290 psi using a rotary knob. Its spindle with 14 full rotations is generously sized to allow very fine flow gradations and has virtually no hysteresis. An alternative is a digital knob with 1499 divisions and a locking ring, this allows any target value to be set rapidly, precisely and with high repeatability.

However, the metering device boasts many additional special features, explains valve specialist Andreas Heyer, “We have redeveloped precision metering technology from scratch.” He continued, “A hollow-cylinder, sintered body forms the regulating core element.”

... to continue reading you must be subscribed